Companies are increasingly recognizing the importance of efficiently organizing personnel transportation. Business trips, employee transportation to and from work sites, and travel between work sites can significantly impact an enterprise’s expenses. Additionally, managing these transportation needs can be labor-intensive, requiring the maintenance of trip records, monitoring vehicle usage, and tracking fuel costs.

In this case, we will explore how digitalization has aided the «INK» in enhancing the efficiency of corporate management for employee transportation and optimizing available resources.

The project background and objectives

Video: the project presentation at the SMART OIL&GAS forum

Other implementations in “INK”

Project Background and Objectives

The “INK” employees travel much daily.

The employees of «INK» engage in significant daily travel, encompassing various activities such as commuting within the city, traveling between fields, airport transfers, and transportation to and from work sites. To facilitate these transportations, the company utilizes its own fleet of vehicles as well as rental vehicles. This entails a diverse range of vehicles, from sedans for city transportation in Irkutsk to off-road vehicles and crew-change buses for field travel.

In 2020, «INK» embarked on the digitalization process of managing passenger transportation. The initiative aimed to address the following tasks:

- To increase the accessibility of vehicles for transportation

At the time when the project was launched, the bulk of the light cars were assigned to individual subdivisions or employees. Unassigned cars were missing, that is why many orders for transportation had to be dismissed.

- To increase the vehicle utilization ratio

Assigning vehicles to specific subdivisions led to situations where cars would remain idle, waiting for passengers instead of actively transporting them. This resulted in a low vehicle fleet utilization ratio. The lack of automation in transportation management required dispatchers to manually assign vehicles for each trip, without a clear visual overview of vehicle availability. These limitations hindered the efficient utilization of vehicles and called for improvements in the transportation management process.

- To optimize the management of the employee transportation cycle

The lack of proper automation in the order management process led to a significant number of manual operations and phone calls between dispatchers, passengers, and drivers. This also included the time-consuming task of preparing reports on the actual usage of vehicles.

The Achievements

“The implementation of the Magenta platform helped to bring to life the changes that had been ripe for a long time. We have optimized the employee transportation management system, increased the service level for employees making trips by service exigency. The vehicle capacity utilization by certain types of transport has increased from 34% up to 76%” — said Natalya Bagduyeva, the lead consultant for practical implementation of information systems in “INK”.

The portal and mobile applications for passengers and drivers

One of the tasks was to simplify the process of requesting and processing travel arrangements. Previously, requests were received through phone calls, paper forms, or electronically, without a standardized format. This created complexity for dispatchers in managing the requests.

We also aimed to streamline communication processes with passengers and drivers. Previously, dispatchers had to constantly communicate with both parties to gather accurate information.

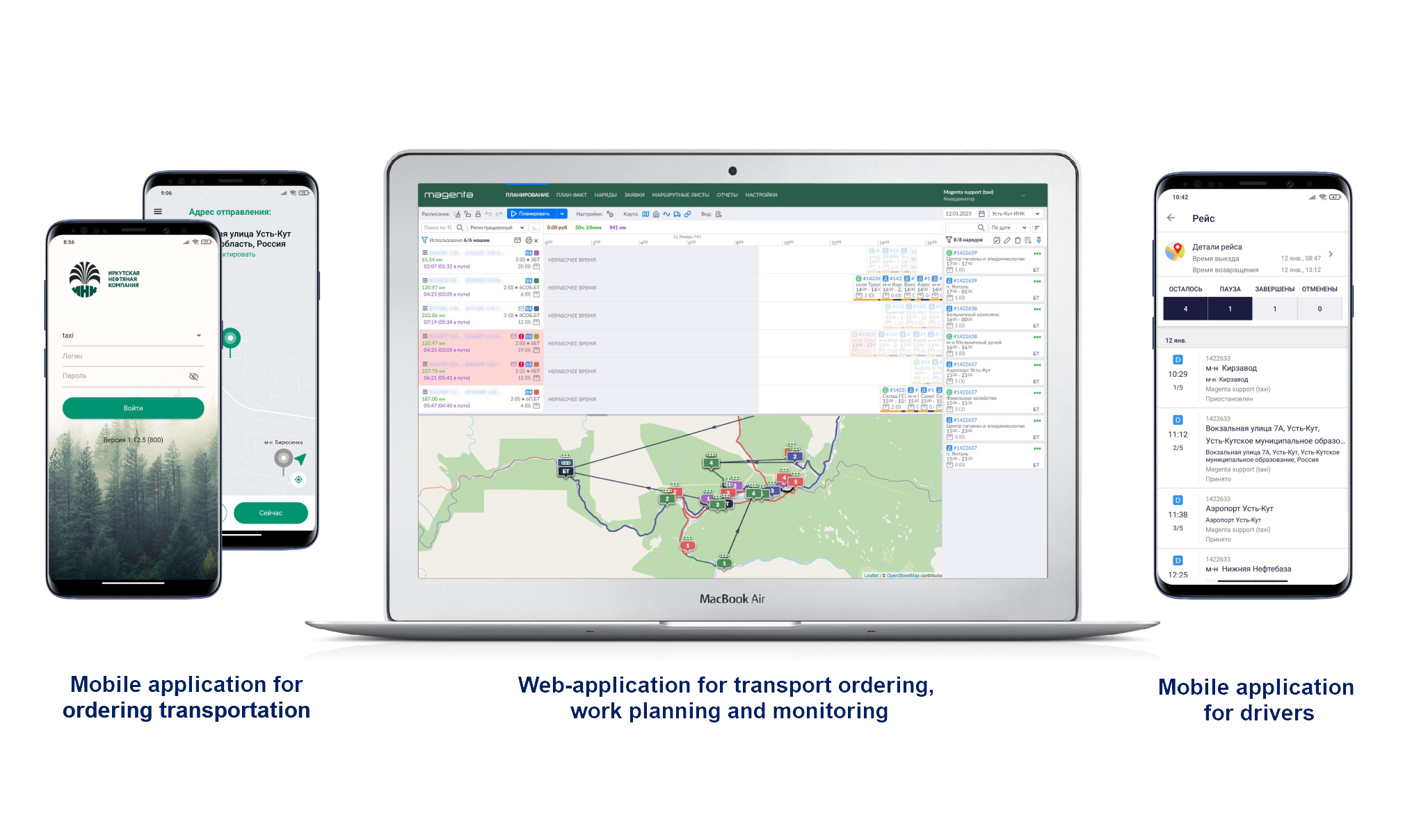

It was evident that all participants in the process should have access to a shared information space, and information exchange should be automated as much as possible. To address this, the Magenta portal and mobile applications for passengers and drivers were developed.

Using the portal and its applications employees can operatively request for a trip for themselves or their manager.

When a travel request is submitted, it includes various details such as the boarding or landing location (following the internal handbook), the number of passengers, the pickup time, arrival time, intermediate stops, luggage or equipment presence, haulage requirements etc. These orders are transmitted to the platform’s logistic module in a standardized format.

The system notifies passengers about their assigned vehicle and pickup time through the mobile application or by sending an email to the customer. The application also allows passengers to track the vehicle’s movement on a map.

The driver’s application receives a planned schedule and relevant order details, while also providing navigation assistance to the boarding or landing location.

By default, the driver’s application sends real-time vehicle location and order delivery status data to the monitoring module. This provides dispatchers with a clear picture of resource availability and eliminates the need to call drivers to verify their ability to fulfill the next order.

The application has reduced the number of phone calls between drivers and dispatchers by half.

The vehicle capacity utilization ratio increased of certain types of transport from 34% up to 76%.

To increase the accessibility of vehicles for trips, we had to solve a number of tasks: to reduce vehicle idle time, to provide for the maximum occupancy of a vehicle, to reduce the duration of trips due to route optimization.

Shared trips – to increase the occupancy of vehicles

The Magenta logistic module analyzes incoming orders and combines them depending on their features, which makes it possible to increase the utilization efficiency of vehicles.

Combining orders into shared routes takes place by default. The system suggests an economically profitable variant for timely delivery of all the passengers to their destination points.

Optimal routes – for quick provision of vehicles and cost reduction

To address the task of haulage routing, several specific factors needed to be considered. Firstly, there were certain roads that became inaccessible during specific seasons, and these industrial roads, totaling 1900 km within «INK,» were not included in publicly available maps. To overcome this, our team manually mapped these roads and marked their seasonal accessibility.

With the implementation of Magenta, we can now plan haulage operations taking into account the actual availability of the vehicle fleet, the required pick-up and delivery times, and the maximum allowable trip duration while optimizing costs. This ensures efficient and optimized logistics for overhauls and transportation operations.

Monitoring trip completion to reduce idle time

Upon arriving at the destination, the driver confirms the arrival in the driver’s software, which notifies the Magenta module that the vehicle is available for the next trip. Similarly, the passenger acknowledges the completion of their journey in their mobile application and has the option to provide feedback on the service quality. This enables accurate cost calculations and allows for monitoring the quality of transport services.

As a result of the quick and efficient allocation of vehicles for trips, there has been a reduction in the need to assign vehicles to individual employees. This shift towards a more flexible car fleet management approach, akin to the concept of «Uberisation,» has significantly contributed to an increased vehicle capacity utilization ratio. Specifically, the utilization ratio for certain types of transport has risen from 34% to 76%.

After the first year of commercial operation of the Magenta platform, we have gathered a substantial amount of statistical data within «INK.» By analyzing the most popular routes, we have successfully introduced a number of commuter buses to further enhance transportation options for our employees.

Video: the project presentation at the SMART OIL & GAS forum

See the speech made by the lead consultant on the practical implementation of information systems in The “Irkutsk Oil Company” Natalya Bagdueva at the SMART OIL & GAS forum, September 2022.